Flanges

Discover our flanges

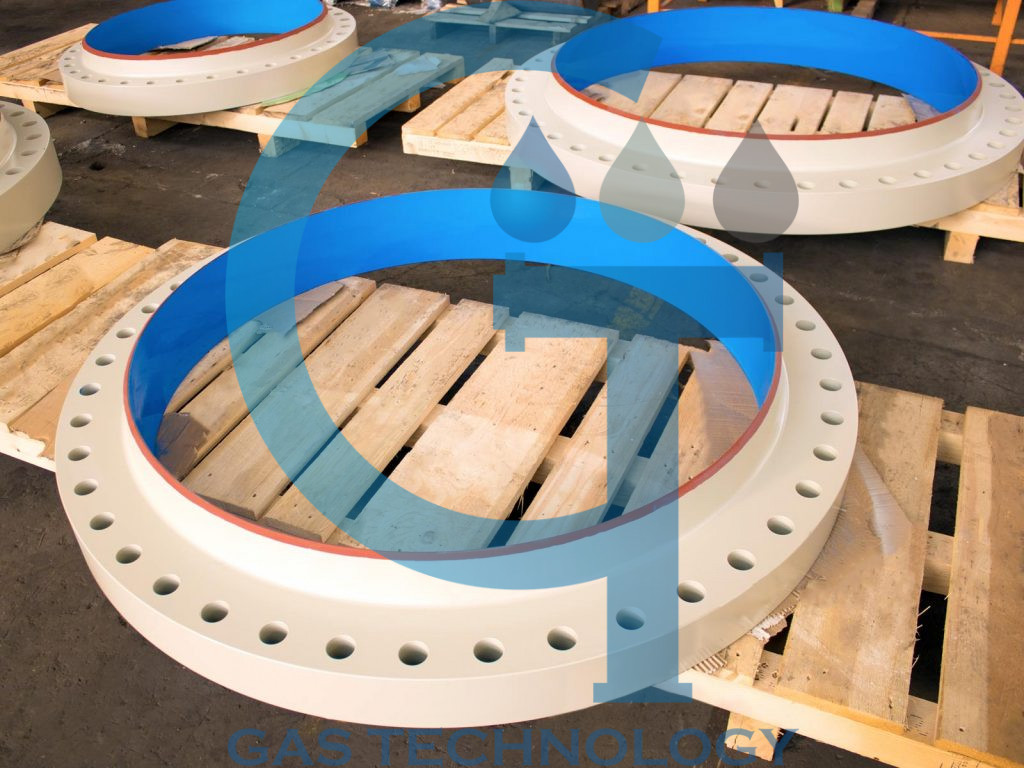

GAS Tech produces and distributes flanges from ½” to 120” in size for all types of industrial applications around the world, thanks to our agreements with an Italian partner.

A flange is a plate or ring that attaches to a pipe, valve, pump, or other piece of equipment with the purpose of providing extra support for strength, blocking off a pipeline, implementing a secure attachment to other items, and more. They are usually connected by welding or with nuts and bolts and can be found throughout or at the end of various pipeline connections.

Our flanges can be customized to meet any specifications and are always manufactured according to international standard such as ANSI or ASME and many more. The most common ANSI/ASME pressure classes are 150#, 300#, 400#, 600#, 900#, 1500#, and 2500#.

Flanges provide easy access for cleaning, maintenance, and inspection of the various sections throughout the entire piping system and are designed in such a way that minimizes downtime during installation and repair. While flanges can be manufactured in a variety of materials, we use only the best types of forged stainless steel, carbon steel, and other various steel alloys.

Our solutions

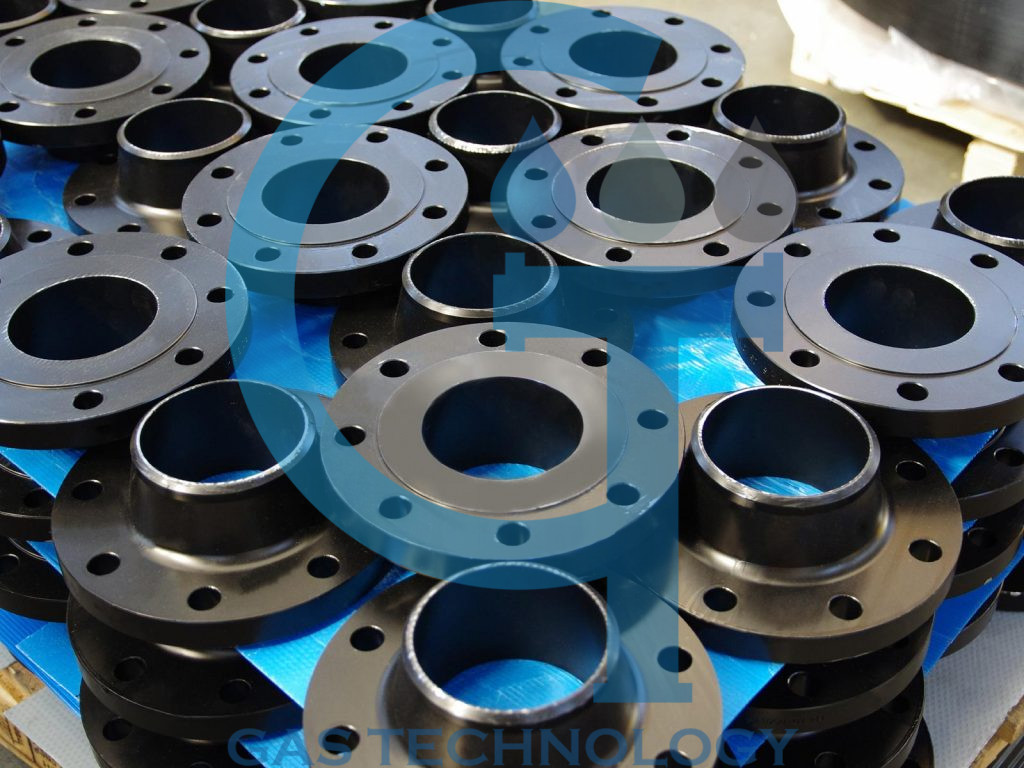

The three main types of flanges produced by GAS Tech are welding neck, socket welded, and blind flanges. Each type of flange has its own, unique characteristics, but all serve to improve the functionality of the various parts of a piping system.

Welding neck flanges are easy to recognize and are commonly used in several applications including high-pressure and sub-zero or high temperatures. These flanges are regularly found when branching pipes from a tank or vessel, allowing for a smooth transfer of stress to the connecting pipe or other equipment.

“Long” welding neck flanges serve the same purpose but act as an extension of the standard weld neck flange. The “long” neck allows for even easier access to a tank or vessel and can sometimes serve to replace small sections of piping.

Socket Weld flanges are popular for small-bore, high-pressure pipes, but can also be found in larger, low pressure piping systems as well. These flanges are attached by inserting the pipe into the socket end, providing stability, and then connected with a fillet weld around the top of the connection. This allows for a better flow of the fluid or gas in the pipe.

Blind flanges are manufactured without a bore and are used to block off the ends of piping, valves, and other pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges are the most highly stressed of all. They are also used for pressure testing the flow through a pipe system.

All flanges come with one of 4 types of finish: stock, spiral serrated (phonographic), concentric serrated, or smooth.