Ball Valves

Discover our ball valves

GAS Tech designs and manufactures ball valves with decades of experience and know-how of the best European engineers and machinists because of our partnership with Italian valve manufacturer. We produce ball valves of all types and for all applications, ranging in size from ¼” all the way up to 80”. Our ball valves can be used in a wide range of industrial sectors including oil and gas, chemical and petrochemical, water and wastewater management, power generation, nuclear power, renewable energy, and more.

Ideal solutions for all your needs

The ball valves produced by GAS Tech are manufactured in compliance with the highest international standards and are available in a wide range of styles and are equipped for all possible pressure and temperature applications. Two of the main categories are floating type and trunnion mounted.

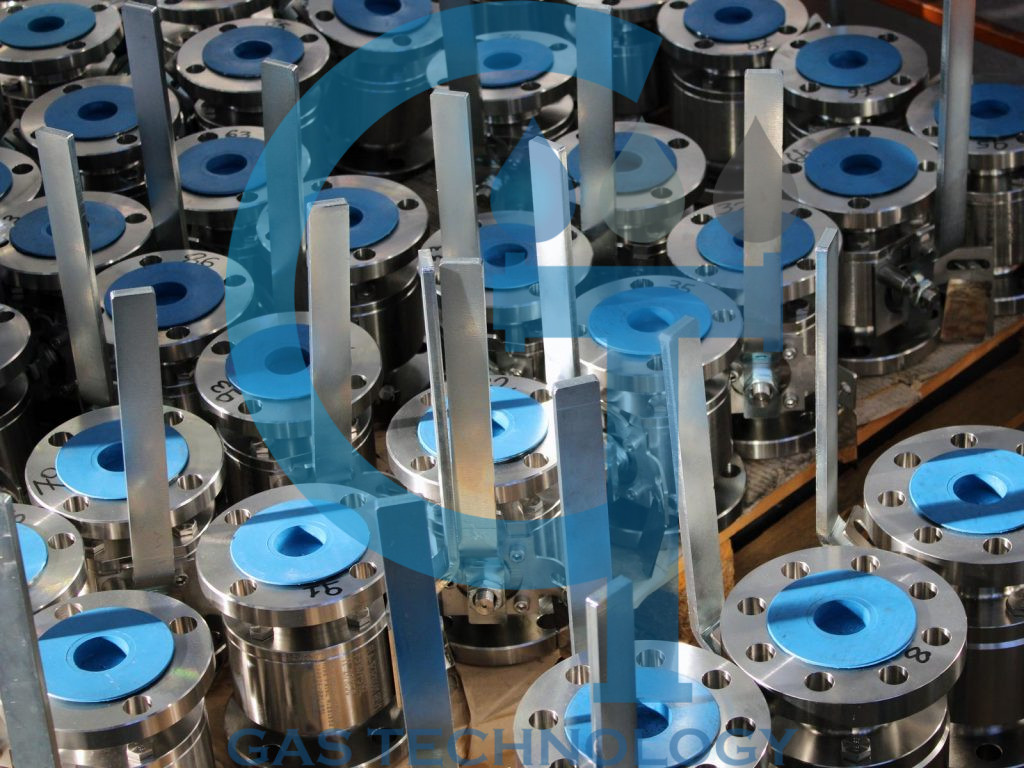

Floating ball valves get their name because of the way the ball (sphere) is suspended between two seats, only attached to the stem. Since the ball is not firmly held in place on its rotational axis it is free to “float” between the two seats. Floating ball valves are commonly used for smaller sizes and low-pressure services. The three main styles of floating ball valves that we provide are monoblock (max. size 4”), side entry (max size. 8” reduced bore), and top entry (max. size 6”).

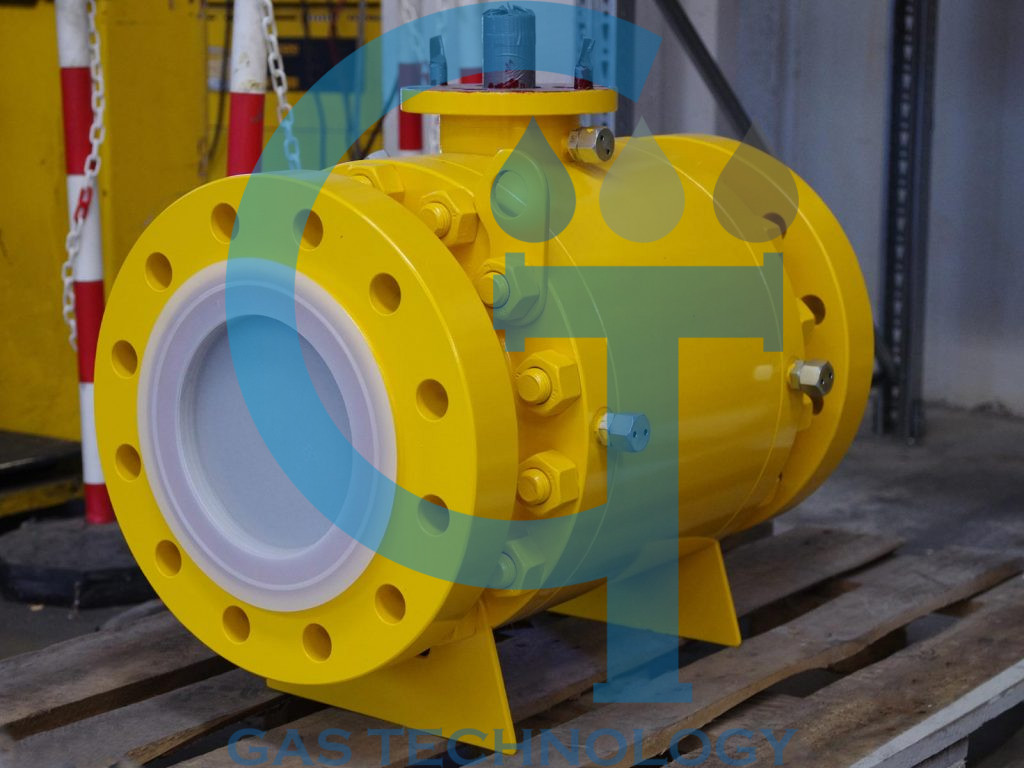

GAS Tech’s trunnion mounted ball valves are designed to permit ease of operation while minimizing operating torque and reducing seat seal wear. In this design, the ball is held in place by the stem and a pin on the rotational axis, commonly known as the trunnion. Trunnion valves are an ideal solution for high pressure and high temperature applications and can provide lower operational costs because any additional stress on the valve is distributed through the trunnion pin in addition to the stem, therefore extending valve life and reducing torque.

The most commonly used types of trunnion mounted ball valves include top entry, two and three-piece side entry, and fully welded body. Our top entry ball valves reach up to 80”, are generally manufactured in cast iron, and are assembled from the top and require minimal disassembly for in-line maintenance of the internal parts.

As the name suggests, our side entry ball valves are assembled laterally, from the side. The two-piece design only reaches a maximum size of 4” while the three-piece design can be as large as 80”. In these valves, each piece of the valve is typically assembled by bolt and allow for easy maintenance. They are suitable for high pressure applications and are often used for truncated or connect piping.

The fully welded design is especially suited to minimize the chance of leakage over time and serve as an economical solution for use under extreme conditions.

Other types of ball valves that Gastec produces include cryogenic, for temperatures as low as -196°C, high temperature for temperatures up to 650°C, subsea, and multi-way or multi-directional.

GAS Tech is driven by a strong desire to improve and work on new, innovative ideas. Our expert know-how and the most up to date 2D and 3D CAD software and other technologies has allowed us to develop customized products that can meet all the demands and requirements of our clients.