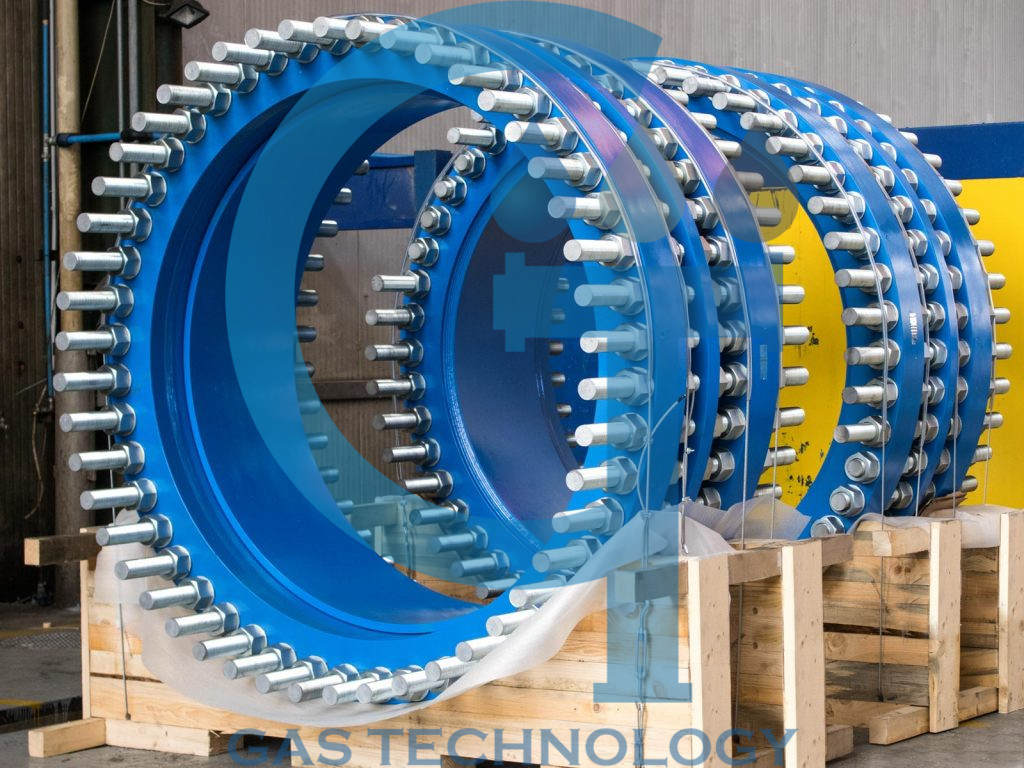

Dismantling Joints

Discover our dismantling joints

GAS Tech dismantling joints play a critical role in the design and layout of pipeline and valve systems. Our dismantling joint is a specialized fitting made of three flanges; two main large flanges that overlap, with a third flange serving to provide a hydraulic seal by means of external pressure applied by the external threaded bars.

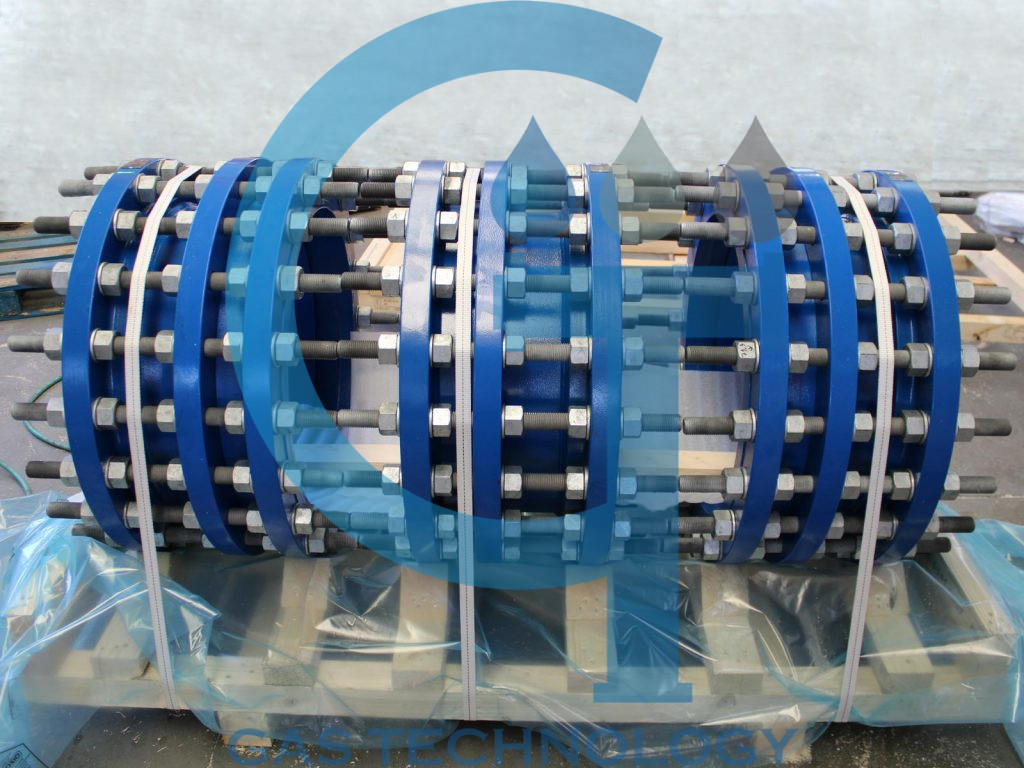

Dismantling joints are an essential piece that help provide a quick and easy solution for installation and removal, or maintenance of a pipe section, valve, pump, or other piece of equipment that you may find in a pipeline. They offer longitudinal adjustment of +/- 25mm (up to 50mm total) allowing 2 separate pieces to come together with precision alignment.

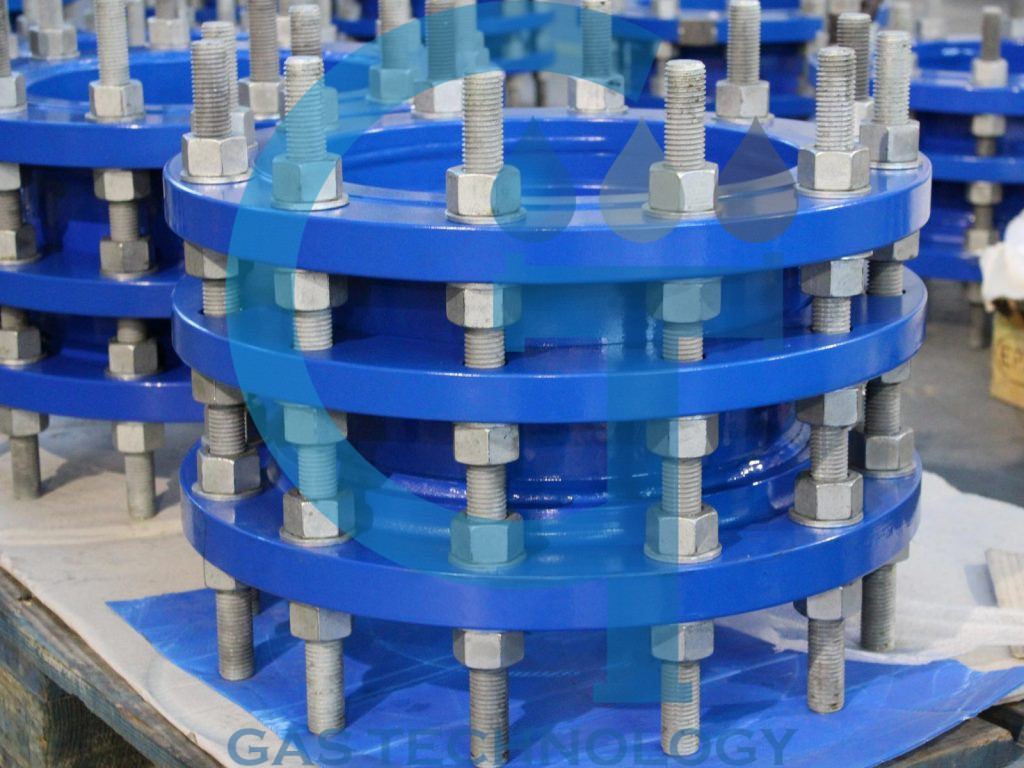

Our dismantling joints are connected with a series of long, threaded tie-rods and bolts. The tightening of these tie-rods provides the necessary force between the gasket and internal flange to create the hydraulic seal between the two main flanges.

Simplicity and versatility

Dismantling joints follow the same pressure classes used for flanges according to ANSI/ASME standards and are class 150, 300, 400, 600, 900, 1500, and 2500. Dismantling joints are usually, but not always, the same material as the equipment that they will be attached to. At GAS Tech, they are usually forged stainless or carbon steel and often coated in fusion bonded epoxy (FBE) but can also be manufactured in various other steel alloys and materials upon request.

The special design standards for our dismantling joints (potable/drinking water) are that they are WRAS certified, can withstand temperatures in the range of -50°C to 150°C, are produced and tested in accordance with AWWA C219, and have an internal lining of “FBE” min. DFT 500 microns suitable for contact with potable/drinking water.

Our carbon steel dismantling joints are always painted inside and outside, whereas the stainless-steel (and alloys) are painted only per customer specifications. Of course, for applications outside of potable/drinking water we always manufacture our dismantling joints in respect to the highest international standards.

The simplicity and versatility of our dismantling joints makes them suitable for a variety of applications including, but not limited to water treatment plants, pumping stations, plant facilities, sewage treatment plants, power generation and meter chambers.